Steel Fabrication Excellence with B&W Contractors, Inc.

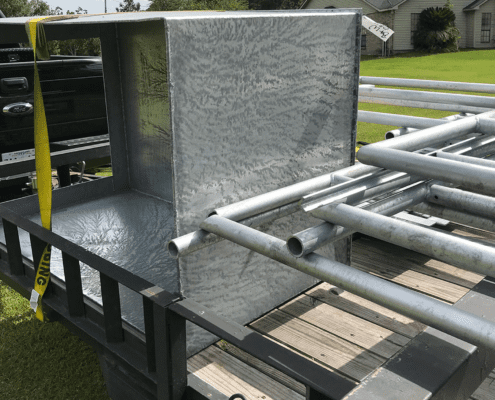

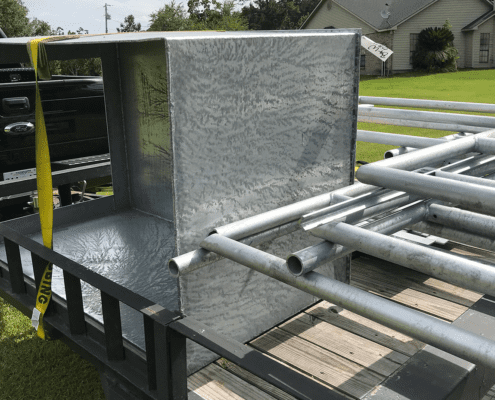

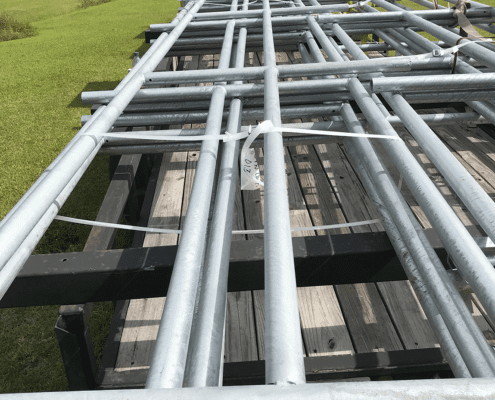

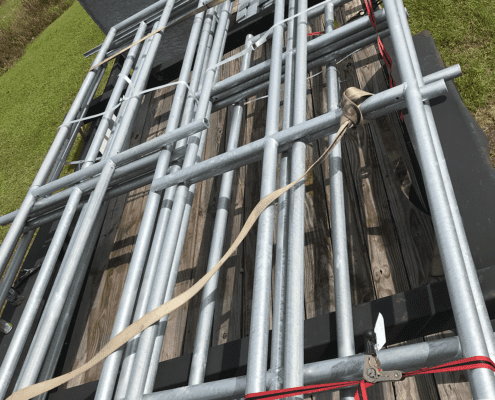

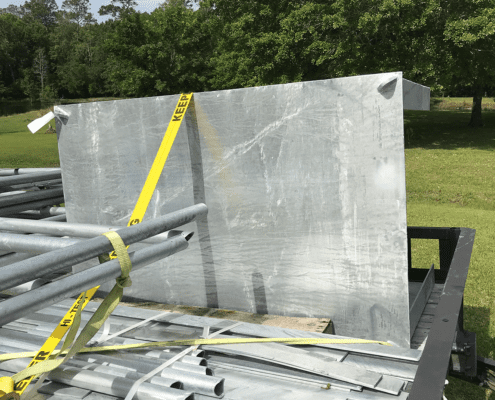

NASA Stennis A1 Test Stand Handrail

At B&W Contractors, Inc., we take immense pride in our steel fabrication capabilities, demonstrated in our recent project involving the fabrication of handrails for NASA’s A1 Test Stand at Stennis Space Center. This project showcases our commitment to quality, precision, and safety in the aerospace sector, where reliable structures are crucial for operational success.

Steel fabrication is pivotal in constructing robust, durable components for various industrial applications. Known for its strength and versatility, steel is an ideal choice for supporting structures, particularly in high-stakes environments like aerospace testing facilities. At B&W Contractors, Inc., we leverage advanced fabrication techniques and industry best practices to ensure our products meet the stringent requirements of our clients.

Project Overview: Steel Fabrication

A1 Test Stand Handrail

The A1 Test Stand is integral to NASA’s rocket testing operations, serving as a critical facility for evaluating rocket engines. With the objective of enhancing safety for personnel working in and around the test stand, our team was commissioned to fabricate high-quality handrails that would withstand the rigors of the testing environment while ensuring compliance with safety standards.

Project Assessment & Material Selection

Before commencing fabrication, we conducted a thorough assessment of the A1 Test Stand’s layout and existing safety protocols. This initial evaluation informed our design approach, allowing us to tailor the handrail dimensions and specifications to integrate seamlessly with the facility’s architecture. We selected high-grade steel for its durability, ensuring that the handrails would provide long-lasting performance under demanding conditions.

Steel Fabrication

Process & Quality Assurance

Our steel fabrication process involved cutting, welding, and assembling the handrails with precision. Utilizing state-of-the-art equipment and skilled labor, we ensured that each component was manufactured to exact specifications. Throughout the fabrication phase, we emphasized quality assurance, conducting rigorous inspections to verify structural integrity and adherence to safety standards.

Regular communication with NASA representatives was essential, facilitating updates and addressing any modifications promptly. This collaborative approach ensured the project was completed on time and within budget, meeting NASA’s high standards of excellence.

Results and Benefits

The successful fabrication and installation of the handrails at the A1 Test Stand significantly enhanced safety for personnel during testing operations. The high-quality steel components not only provide reliable support but also contribute to the overall integrity of the facility. By prioritizing safety and quality in our steel fabrication processes, B&W Contractors, Inc. reinforced its reputation as a trusted partner in the aerospace industry.

Conclusion

At B&W Contractors, Inc., our expertise in steel fabrication is exemplified through our successful projects with esteemed organizations like NASA. We remain dedicated to delivering innovative solutions that meet the unique needs of our clients. For more information about our fabrication services or to discuss your project requirements, please contact us. Together, let’s create structures that ensure safety and operational excellence.